Springs have a massive impact on the way your suspension components interact with one another, which consequently affects your ride quality and handling.

When combined, springs and dampers control the relative motion between sprung and unsprung masses of your car, influencing tire traction and overall handling. Despite that, many coilover brands focus a ton of their R&D on just the dampers; springs are usually plonked on as an afterthought to keep costs down.

Many of us run those springs without thinking about upgrading them, which can be attributed to the notion that all automotive springs are pretty much the same, which isn’t true.

Materials and processes used to manufacture springs play a vital role in the resulting quality, which is a good thing because it unlocks avenues for variation.

For example, springs designed for industrial stress-test machines will prioritize durability over everything else, while those developed for motorsport favor a much higher range of travel and low weight.

By improving the manufacturing process, these characteristics can be significantly altered, and that’s exactly what Swift Springs is famous for. There’s a reason they’ve been a big name in the spring business for over 9 decades. Read on to learn more.

Qualities You Don’t Want in Your Springs

Before we discuss the Swift Springs brand and what they do differently, let’s take a quick look at some attributes you absolutely do not want in automotive springs.

That way, you’ll know what to look for when you’re buying your next set. Knowing this stuff will also help you spot any potential issues that your current springs might have.

Inconsistent Spring Rate

When it comes to spring quality, consistency is the name of the game. The problem with inconsistent quality is that you never truly know when something’s going to stop working the way it’s supposed to.

For those not in the know, spring rate refers to the amount of weight required to compress a coil spring by a certain amount. The industry standard unit for measuring spring rates is either kg/mm or lb/inch.

For example,

- 10 kg/mm: 10 kilograms of weight is required to compress the spring by 1 millimeter

- 10 lb/in: 10 pounds of weight is required to compress the spring by 1 inch

Choosing the right spring rate is incredibly important. It needs to match the weight of your car, engine placement, and driving style.

However, when springs get older, or if they’re poorly made, the rate fluctuates at different points in the compression range. This is especially common with springs that have a very low spring rate to begin with, even if they’re brand new.

Unless you have access to a spring dyno, it’s difficult to spot these inconsistencies.

That said, most springs don’t keep their original specs forever. Eventually, they will give you problems as they get older and wear out. It’s just a matter of how much you can delay that process.

Coil Bind & Spring Bind

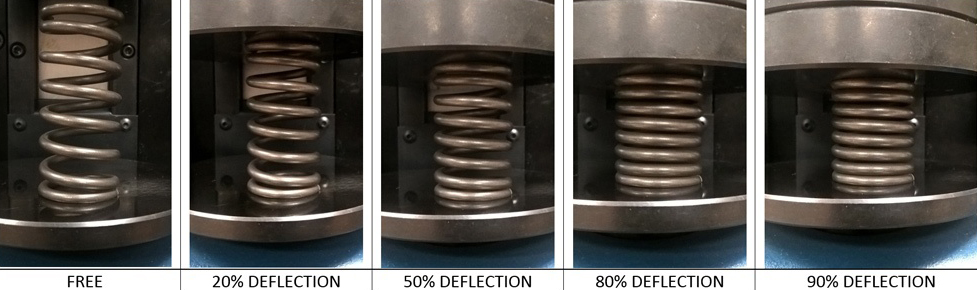

Spring bind and coil bind are terms that are often used interchangeably. Coil bind is what happens when a spring fully compresses and all the coils bind together. At that point, it essentially turns into a solid piece of metal. This is entirely a spring-related issue.

Spring bind is when the spring doesn’t rotate properly with the rest of the strut when turning. This problem is exclusive to front suspensions because they’re connected to the steering system.

When your springs bind, you’ll hear a pinging sound while turning. This problem commonly occurs with coilovers when the bearings on the upper mount have gone bad. As a result, the spring can’t turn freely and so it skips across the perches.

Of the two, coil binding is a bigger problem.

Sag

Sag is what happens when springs lose some amount of stroke (length) over time because of wear or poor quality. Springs that sag over time and are prone to coil binding.

Spring sag reduces your suspension’s ability to support its normal load. Any more than an inch of sag indicates that your springs have worn out.

What Are Swift Springs?

Swift Springs is a company that dates back to 1997. It started out as the motorsports division of Tokyo Hatsujo Manufacturing — an industry leader in the spring business since 1924.

Backed by decades of manufacturing experience and expertise, the company set out into the auto racing market with one goal: to make the best aftermarket springs possible.

They wanted to create springs that were light, durable, and cost effective despite being race-ready, which is exactly what they did.

Designing motorsport suspension springs is as much an art as it is a science. Tuners and technicians know that maintaining proper traction and a flat contact patch around turns is the key to stability and faster lap times.

With that in mind, the engineers at Tohatsu set out to produce an entirely new steel alloy from the ground up called HS5.TW, which is far superior to silicone chrome steel that you’ll see in most OEM and aftermarket springs.

This proprietary material, along with other trade secrets they’ve accumulated over the years, allows them to manufacture the iconic Swift springs.

Swift’s technological prowess lifted many world class race teams to a podium finish in motorsports such as 24hrs of Le Mans, Formula Three, Super GT (JGTC), and Nurburgring 24hrs.

They’ve been involved in several racing disciplines, including rally, autocross, drifting, motorcycles, and many more.

Why Swift Springs?

There are 4 key qualities that spring manufacturers strive to achieve:

- Consistent spring rate throughout the stroke

- Getting the maximum stroke possible

- Resistance against sag or loss of spring height

- Light weight

These features play a crucial role for spring performance. Swift’s cold winding techniques, combined with the unique HS5.TW alloy, allow them to get the recipe just right.

Swift springs are barrel shaped as opposed to round, and they have differently designed cross-sections compared to regular springs.

That’s why they require fewer coils per inch compared to an equivalent spring with the same spring rate, making them less likely to bind. There’s also the added advantage of more stroke along with a higher bottom-out ceiling.

This makes them lighter, which is great because any amount of weight shaved off from the unsprung parts of your car is always a welcome addition. Lighter springs make for faster reaction times and consistent feedback.

Another cool thing about Swift Springs is that they exhibit little to no sag, which means they don’t droop over time. They’re known for maintaining a consistent spring rate throughout the stroke length. We’re talking 0.5-1.0% variation, whether they’re brand new or a year old.

All of this translates to a noticeable increase in traction, smoother weight transfer, and improved ride quality. That said, noticing these differences does require a good amount of seat time and experience.

Conclusion: Do They Live Up to the Hype?

When you compare the price of standard lowering springs from brands like Eibach, H&R, Hypercoil, Vogtland, Tanabe, Tein, and the like, you’ll notice that Swift Springs are more expensive compared.

Considering all that, along with all the positive reviews and clever marketing, it’s not uncommon for many of us to not question the hype or wonder if these springs are too good to be true.

One thing is for sure, Swift Springs’ parent company has some of the best manufacturing processes in the industry, and their testing process is off the charts.

That said, springs are a stress-bearing component, and they’re not exactly bullet proof, no matter how they’re made. They will require a replacement at some point, but not nearly as soon as some other springs do.

In conclusion, yes. Swift Springs live up to the hype, but at the same time, they aren’t exactly magic pixie dust. As long as you have realistic expectations, choose the right spring rates and pair them with the right dampers, you’ll definitely get your money’s worth.

Have you or someone you know used Swift Springs before? How was the experience? Let us know by leaving a comment below.

If you enjoyed reading this post, share it with your friends on Reddit, Facebook, or your favorite online communities. We appreciate your support!